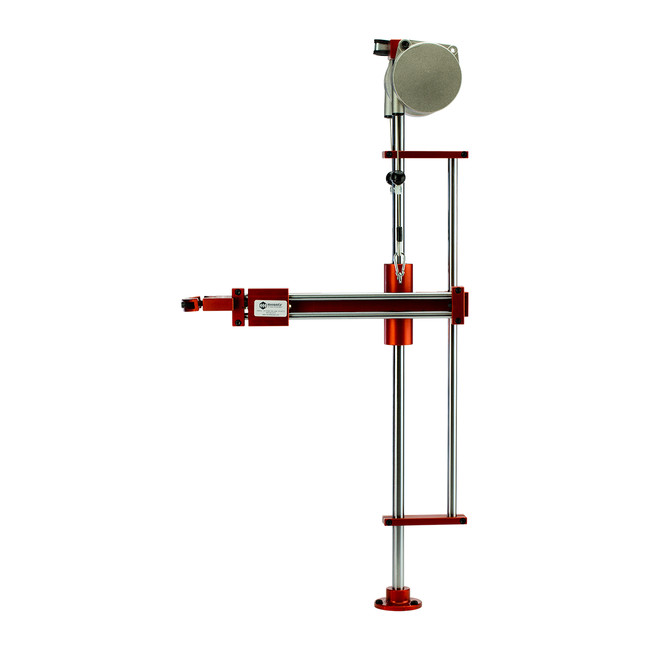

BFA-Series Robotic Electric Screwdrivers

Designed for robotic and automated torque applications, the BFA-Series robotic electric screwdrivers feature a high-performance brushless motor design that provides durability and reduces the typical maintenance costs associated with brush type robotic electric screwdrivers.

High-speed, high-volume assemblies, involving seemingly endless repetitive motions, yet demand meticulous attention to detail, are often best accomplished using robotic screwdrivers. The durable automation tools deliver reliability and precision torque control at every turn. The assembly automation tools ensure accuracy with a precision automatic shut-off clutch once the preset torque is achieved in the fastening process.

The BFA robotic screwdrivers are ESD-safe, ensuring a resistance of less than 1 Ohm at the bit tip. ESD management in power tools ensures product quality, cost savings, and a reduction in overall ESD failures. Manufacturing engineers involved with microelectronic products know the importance of controlling Electrostatic Discharge (ESD) failures. Lapses in preventing electrostatic discharge can impact production yields, manufacturing costs, product quality, reliability, reputation, and profitability.

If you need a driver with a higher torque range, check out our NFA-Series brushless robotic drivers.

If you need a driver with a higher torque range, check out our NFA-Series brushless robotic drivers.

![]()

![]()

![]()

- Description

Description

CHOOSE THE MODEL BELOW

| Model: | Socket Head Power Bits 1/20 x 2″ |

| Item Name / Number: | 121039 |

| Bit Hex Size: | 1/20″ |

| Bit Length(IN): | 2″ |

| Package Quantity |

- Various models that range from 0.9 – 10.4 lbf.in

- Robotic style electric screwdriver for automated and fixtured applications.

- Drivers include a front mounting flange.

- High performance brushless motor design provides durability and reduces the standard maintenance costs for electric screwdrivers.

- Designed for high production environments. Minimal heat build-up even when tool is operated continuously.

- Over Heat Protection (OHP) and Over Current Protection (OCP) protect driver from damage or malfunction. Features a LED display that signals the tool status for the operator to view.

- Can be connected with the Scout Screw Counter.

- Requires STC40-FA transformer (power supply).

- All models are ESD designed and prevent the occurrence of electrostatic discharge, which improves production yields, manufacturing costs, product quality, product reliability, reputation and profitability.

- Ensures accuracy in fastening with precision automatic shut-off clutch once preset torque is achieved.

- External torque adjustment scale.

- Forward and reverse direction by switch. Start and stop output signals.

- Drive Adapters

- Ergonomic Torque Arms

- Screw Counter

- Screw Presenter

- Torque Cover

- Vacuum Adapters

Model : BFA060 ESD

Model : BFA080 ESD

Model : BFA120 ESD