RDA – Run Down Adapters

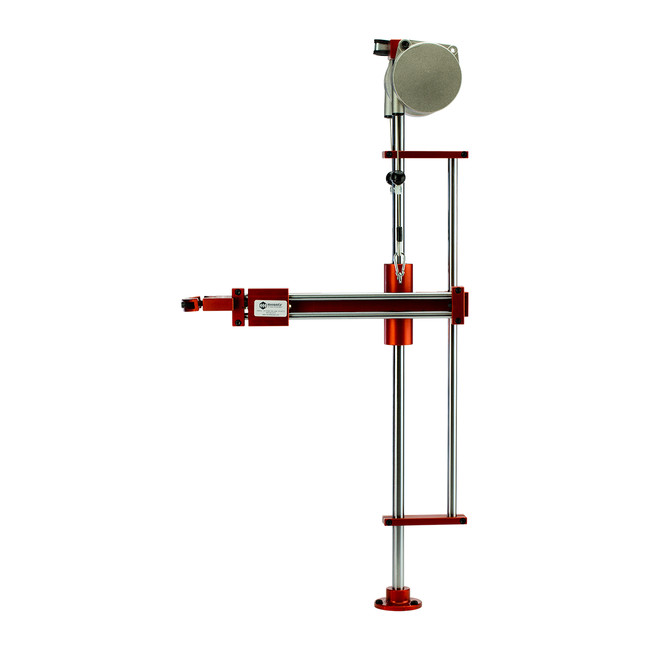

Mountz run down adapters (RDA) are designed to provide consistent and reliable torque readings for power-driven torque control tools. Run down adapters are used to simulate various joint characteristics to provide a more accurate torque reading during testing and calibration.

Run down adapters are mounted in-line between the tool drive and the transducer of a torque analyzer or sensor, reducing the impact and irregular peaks that cause poor testing repeatability.

Each RDA has an effective torque range and will supply repeatable torque data within that range if used correctly. Check out our selection guide chart to select which RDA fits your torque analyzer or sensor the best.

Accurate Power Tool Testing

- Provide consistent and reliable torque readings for power-driven torque control tools.

- RDA is mounted in-line between the tool drive and the transducer of a torque analyzer or sensor.

- Compact to limit spacing between the power tool and torque measurement equipment for improved accuracy and ease of use.

- Operates in a clockwise direction only. After each run down, the RDA should be completely backed-up.

- Description

Description

CHOOSE THE MODEL BELOW

CHOOSE THE MODEL BELOW

| Model: | Socket Head Power Bits 1/20 x 2″ |

| Item Name / Number: | 121039 |

| Bit Hex Size: | 1/20″ |

| Bit Length(IN): | 2″ |

| Package Quantity |

Accurate Power Tool Testing:

-

-

- Provide consistent and reliable torque readings for power-driven torque control tools.

- RDA is mounted in-line between the tool drive and the transducer of a torque analyzer or sensor.

- Compact and lightweight.

- Operates in a clockwise direction only. After each run down, the RDA should be completely backed up.

-

Mountz Quality Standards:

-

- Hardened thread components increase accuracy and life.

- Square drives conform to ASME B107 standards for proper fit.

- Non-rotating body for improved safety.

Torque Analyzers:

The RTSX-A must be connected to a torque analyzer to display a torque reading and store the test data. Compatible with these torque testers:

- TorqueLab LTT Torque Analyzer

- TorqueMate PTT Torque Analyzer

Cables for Connecting RTSX-A to a Torque Analyzer:

Cable must be purchased to connect RTSX-A to LTT & PTT

Improve Your Calibration Process:

Multiplexer: Connect 1-4 torque sensors to the PTT or LTT torque analyzer. Switch between sensors manually or automatically.

Sensor Maintenance and Calibration:

Maintain and calibrate your tools on-site by purchasing calibration equipment to use in-house.

The organization that owns the tool must determine a suitable calibration frequency that meets their needs based on the history of equipment performance, application, degree of usage, and

management objectives.

For most organizations, we recommend 6-month or 12-month calibration intervals.

Calibration Wheels: Engineered for calibrating torque analyzers and sensors and ensuring instruments are traceable to National or International Standards, such as N.I.S.T and ISO.

Calibration Hangers and Weights: Calibrated Dead Weight are the official means by which torque analyzers and torque sensors are calibrated and are traced to National or International Standards, such as N.I.S.T, and ISO.

;