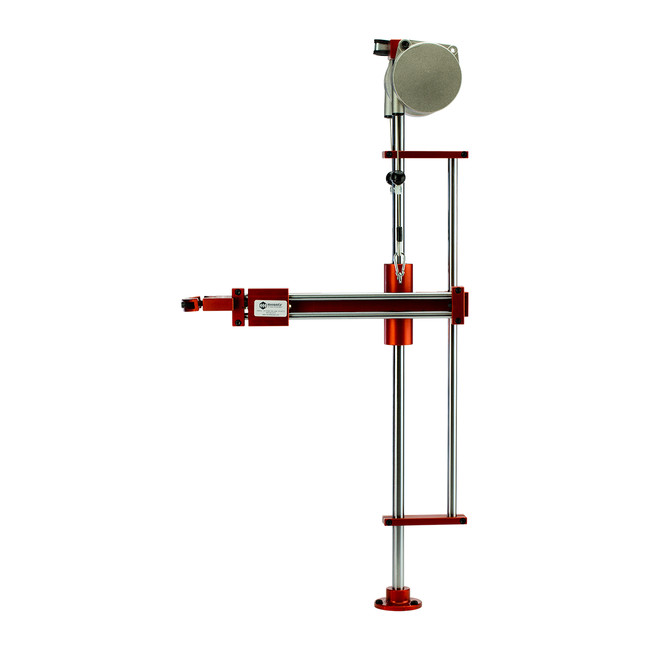

EZ-Slider Torque Arm Tool Clamps

The EZ-Slider 8 & 20 comes with a standard 1/4″ air fitting. An electric tool clamp if sold separately.

- Description

Description

CHOOSE THE MODEL BELOW

CHOOSE THE MODEL BELOW

| Model: | Socket Head Power Bits 1/20 x 2″ |

| Item Name / Number: | 121039 |

| Bit Hex Size: | 1/20″ |

| Bit Length(IN): | 2″ |

| Package Quantity |

- Secure the assembly process by ensuring that every screw is in the correct location at the right torque

- Programmable sequence operation.

- Error proofing.

- Detects – cross threading, omissions, unfinished rundowns and cycle complete.

- Compatible with DC Controlled Tools, torque electric screwdrivers (with transformers or controllers), air tools (ported).

- Password protection and wall mountable.

- Can interface with most intelligent driver systems that store multiple torque programs and has external digital I/O control.

- Eliminates torque reaction of power tools. Can be used with a variety assembly tools.

- Quick and easy to setup. Self teaching and automation program mode.

- Programmable: Positioning Tolerance, Min. and Max. time for Poka Yoke control (automatic or manual) and 99 memory points.

- Crafted with lightweight durable carbon fiber the arm collapses like a telescope.

- Easy-to-use, requires little space and doesn’t disrupt production flow.

- The effortless handling of the torque arm provides comfortable tool operation and increased production.

- Mountable and easy to install on a wall, workbench and a standard rail or trolley system.

- Maintenance free.

- Long arm reach capability up to 6 1/2 ft.

- Operates with touch posi-control device.

- Torque Arm is available in 3 options: APC model – Equipped with one angle coder. LPC model – Equipped with one cable length coder. LAPC model – Equipped with one cable length coder & one angle coder.

Tailored Industrial Support with Quality Products and Expert Guidance.

Our solutions will reduce your bottle necks and improve your efficiency and productivity, contact us now and let us know how we can help you, we are always here!