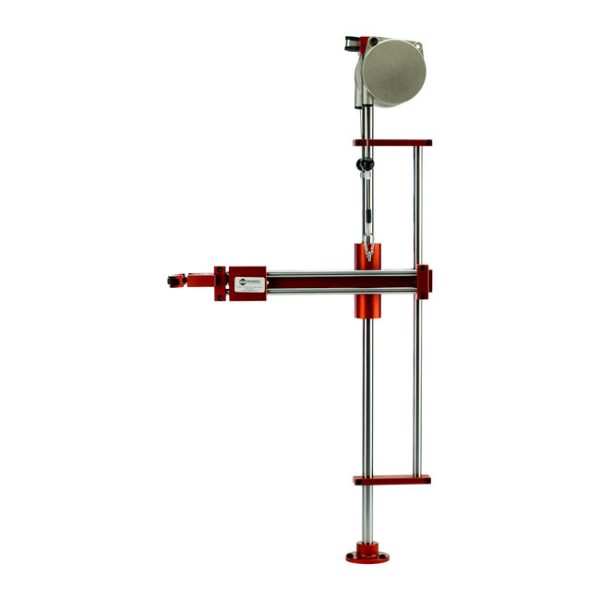

EZ-Glider Position Control Torque Arms

The position control torque arm system helps manufacturers detect and eliminate costly screw-fastening errors during the assembly process. This torque arm is designed to reduce the risk of improperly fastened screws, ensuring that every screw is in the correctly tightened in the correct sequence. A good tightening sequence ensures that an even preload distribution is achieved in the joint. Using a position control arm is like putting the eyes and ears of a quality control manager where they are needed most – right on the assembly area.

- Description

Description

CHOOSE THE MODEL BELOW

CHOOSE THE MODEL BELOW

| Model: | Socket Head Power Bits 1/20 x 2″ |

| Item Name / Number: | 121039 |

| Bit Hex Size: | 1/20″ |

| Bit Length(IN): | 2″ |

| Package Quantity |

- Secure the assembly process by ensuring that every screw is in the correct location at the right torque.

- Programmable sequence operation.

- Error proofing.

- Detects – cross threading, omissions, unfinished rundowns and cycle complete.

- Compatible with DC Controlled Tools, torque electric screwdrivers (with transformers or controllers), air tools (ported).

- Password protection and wall mountable.

- Can interface with most intelligent driver systems that store multiple torque programs and has external digital I/O control.

- Prevents cross threading and side load. Keeps tool perpendicular.

- Reduces RMI (Repetitive Motion Injury) and CTS (Carpal Tunnel Syndrome) while boosting production.

- With the ability to bend like an elbow, the torque arm provides agility to position the tool in a variety of positions for different applications. Arm can be set at an inclination of 0º , 22.5º and 45º .

- Provides smooth flexible range as the arm absorbs torque reactions from electric air screwdrivers, angle nut runners, pulse tools, and pistol grip tools.

- Quick and easy to setup. Self teaching and automation program mode.

- Programmable: Positioning tolerance, Min. and Max. time for Poka Yoke control (automatic or manual) and 99 memory points

- Operates with touch posi-control device.

Tailored Industrial Support with Quality Products and Expert Guidance.

Our solutions will reduce your bottle necks and improve your efficiency and productivity, contact us now and let us know how we can help you, we are always here!