18Apr

03Apr

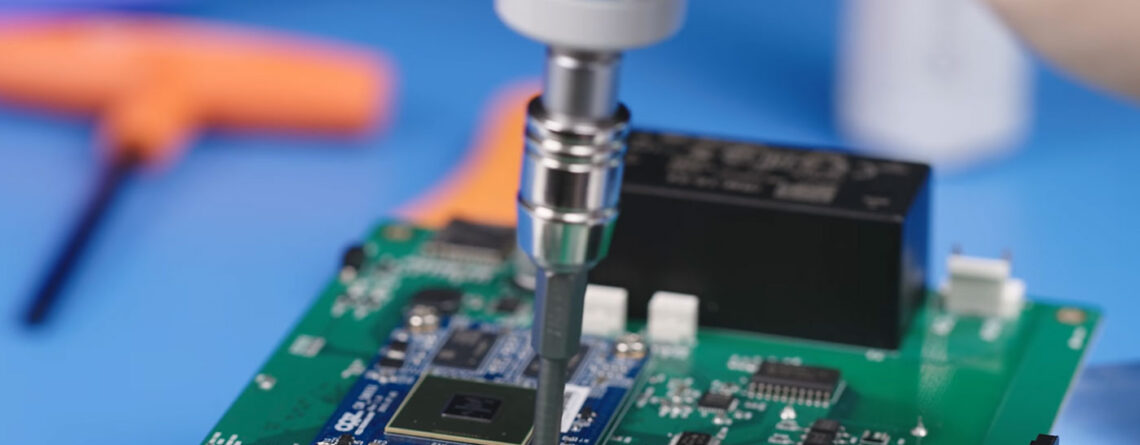

How Cleanroom-Ready Torque Tools Help Reduce Contamination Risk in Precision Manufacturing

Mountz Torque In cutting-edge manufacturing such as semiconductors, electronics, biomedical, and medical device manufacturing, contamination-free assembly is critical. Even a tiny particle or electrostatic discharge can lead to catastrophic failure in delicate parts. That’s why the use of cleanroom-ready torque tools—especially those specifically engineered for ESD protection...

03Mar

5 Tips to Sustain Your Torque Tools’ Accuracy Long-Term

Mountz Torque When it comes to torque tools, accuracy is paramount. Being off by a few percentage points can result in a fastener that's too loose—or too tight—leading to catastrophic failure, compromised safety, or rejected QA lots. For sectors like semiconductors, electronics, aerospace, and medical devices,...

02Feb

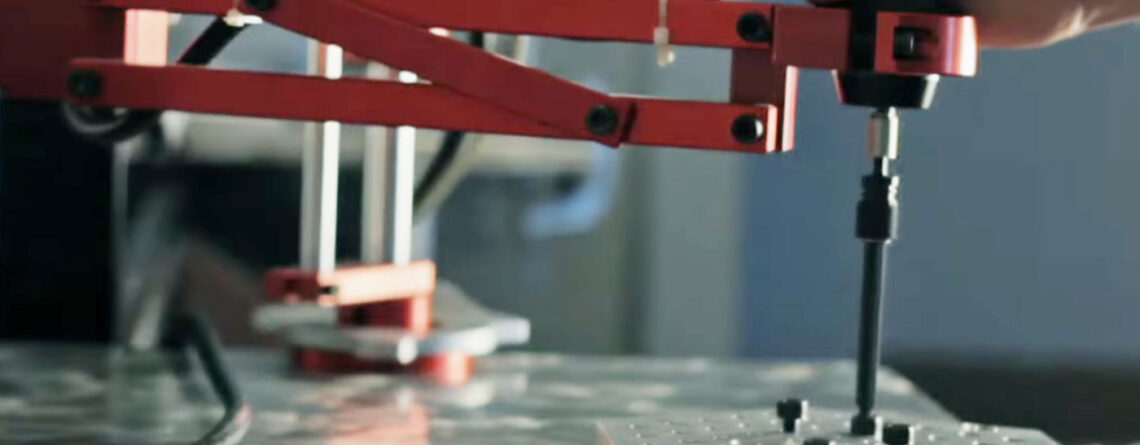

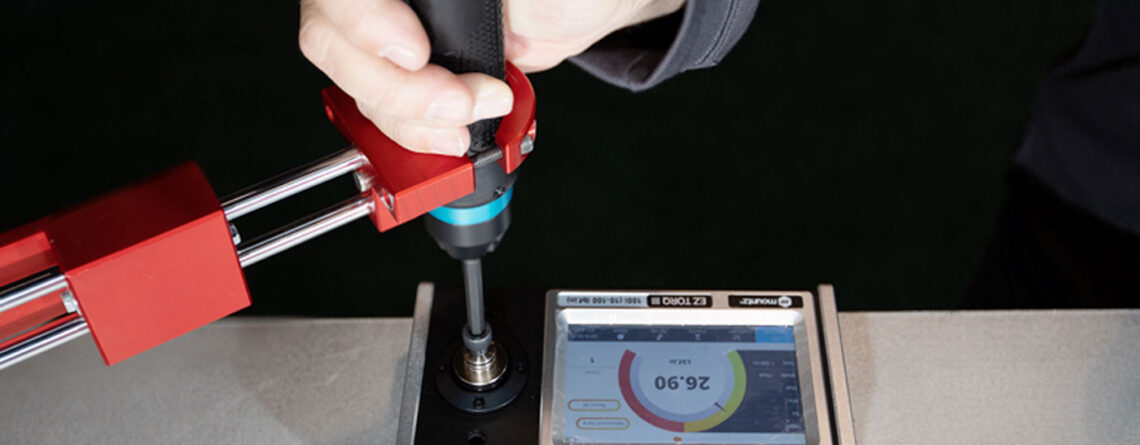

Development of Torque Tools: From Manual to Data-Driven

Mountz Torque Torque screwdrivers were once manual tools with visual or feel feedback. Although sufficient for low-risk applications, there is no means to guarantee and record that the proper torque was achieved. As part of the evolution of smart manufacturing and Industry 4.0, digital torque screwdrivers...

01Jan