18Apr

03Apr

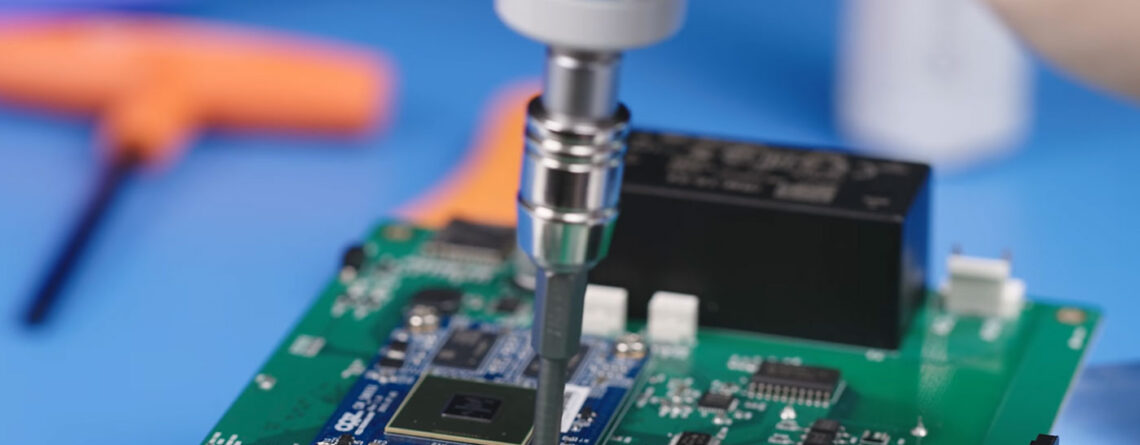

How Cleanroom-Ready Torque Tools Help Reduce Contamination Risk in Precision Manufacturing

Author - pH1l_admin In cutting-edge manufacturing such as semiconductors, electronics, biomedical, and medical device manufacturing, contamination-free assembly is critical. Even a tiny particle or electrostatic discharge can lead to catastrophic failure in delicate parts. That’s why the use of cleanroom-ready torque tools—especially those specifically engineered for ESD...

03Mar

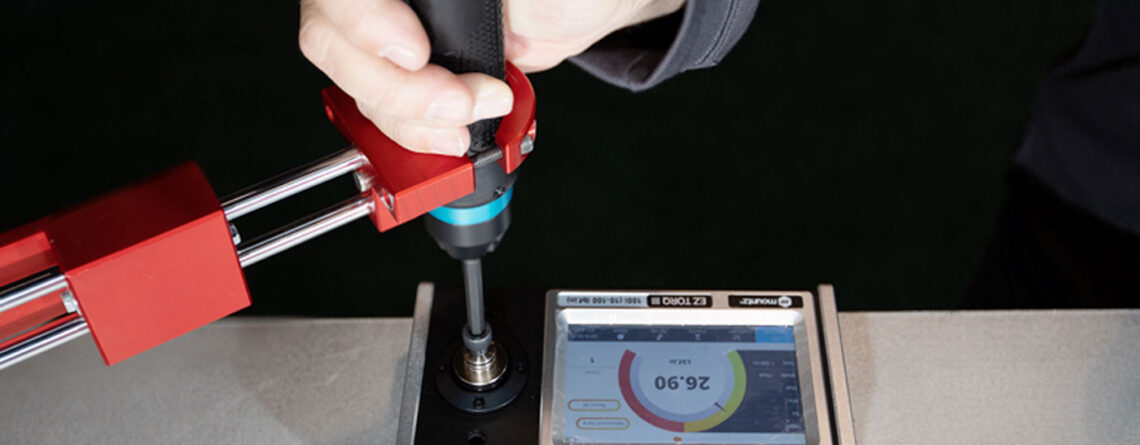

5 Tips to Sustain Your Torque Tools’ Accuracy Long-Term

Author - pH1l_admin When it comes to torque tools, accuracy is paramount. Being off by a few percentage points can result in a fastener that's too loose—or too tight—leading to catastrophic failure, compromised safety, or rejected QA lots. For sectors like semiconductors, electronics, aerospace, and medical...

02Feb

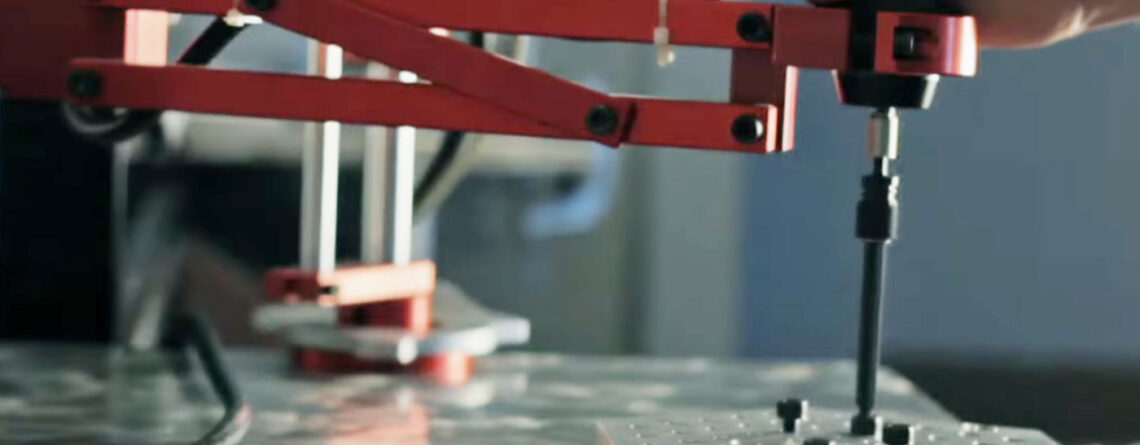

Development of Torque Tools: From Manual to Data-Driven

Author - pH1l_admin Torque screwdrivers were once manual tools with visual or feel feedback. Although sufficient for low-risk applications, there is no means to guarantee and record that the proper torque was achieved. As part of the evolution of smart manufacturing and Industry 4.0, digital torque...

01Jan