Transducerized vs Untransducerized Screwdrivers: Which Is Suitable for Your Precision Assembly Line?

In the precision manufacturing world of today, particularly in the semiconductor, electronics, aerospace, biomedical, and medical device industries, how you tighten one screw can equal product quality, safety, and compliance.

When power assembly tools are being used, the two most prevalent choices for semi-automated or automated tightening are:

- Transducerized Screwdrivers

- Untransducerized (standard electric or pneumatic) Screwdrivers

While both are ubiquitous on assembly lines, they have different functions and provide different levels of control, data feedback, and process capability.

In this post, we’ll discuss what transducerized screwdrivers are, when to utilize them, and how they differ from their untransducerized counterparts—so you can choose the best one for your operation.

What Are Transducerized Screwdrivers?

Transducerized screwdrivers are precision, “smart” torque tools that contain an internal torque transducer and angle encoder. The sensors track the torque and angle of rotation in real time and give feedback to a controller unit or factory MES (Manufacturing Execution System).

Main Features:

- Real-time torque and angle monitoring

- Precision control with closed-loop feedback

- Data capture and traceability for every screw

- Error-proofing (over-torque, cross-threading, etc.)

- Integration with factory automation systems

Mountz EPT-Series Transducerized Screwdrivers provide enhanced programmable control for multiple tightening strategies:

“With torque control and angle monitoring, the EPT transducerized tools can eliminate defects and deliver repeatable tightening in production environments.”

What Are Untransducerized Screwdrivers?

Untransducerized screwdrivers, or standard electric screwdrivers, provide consistent torque through clutch-based or current control systems but without real-time monitoring or digital feedback. They are low-cost and reliable but do not quantify torque values or save tightening data.

Common Types:

- Brushless electric screwdrivers with torque clutch

- Pneumatic screwdrivers (air-driven)

- Standard corded electric screwdrivers

Common Features:

- Preset or variable torque settings

- Clutch disengagement at set torque

- No torque/angle data output

- Lower up-front cost

Feature Comparison: Transducerized vs Untransducerized

| Feature | Transducerized Screwdrivers | Untransducerized Screwdrivers |

| Torque Accuracy | +0.5% - 2% | +5% - 10% |

| Real-Time Feedback | ✔✔✔ | ✖ |

| Torque & Angle Control | ✔✔✔ | ✖ |

| Data Recording | ✔✔✔ | ✖ |

| Traceability | ✔✔✔ | ✖ |

| Error Detection | ✔✔ | ✖ |

| Cost | Higher | Lower |

| Best For | Regulated, high-precision assembly | General-purpose, low-cost assembly |

When to Use Transducerized Screwdrivers

1. In Regulated Industries with Audit Trails

Medical devices, aerospace, and automotive electronics generally need end-to-end torque traceability and records for every fastener to meet FDA, AS9100, or ISO 13485 requirements.

Transducerized screwdrivers deliver:

- Pass/fail information per screw

- Timestamp, torque value, angle, and operator

- MES and quality management system integration

2. In High-Risk Assemblies

If you’re tightening screws that secure:

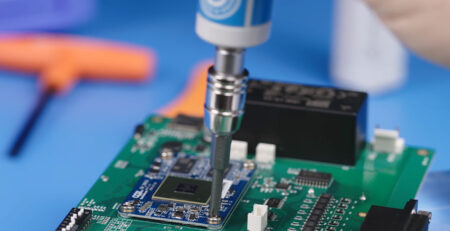

- Circuit boards in surgical devices

- Actuators used in aircraft control systems

- Semiconductor wafer handling parts

- then torque accuracy isn’t merely a quality issue—it’s a safety and liability issue.

3. Empowering Smart Manufacturing and Industry 4.0

Mountz transducerized EPT tools enable:

- Programmable torque-angle strategies

- Interface with Ethernet, Modbus, or other control systems

Application: The EPT controller stores up to 8 tightening programs with varying torque and angle settings—perfect for flexible production lines.

When to Use Untransducerized Screwdrivers

1. In General Assembly with Moderate Tolerances

For applications that do not require complete traceability or very tight torque tolerances, untransducerized tools are low cost and convenient to operate.

Examples:

- Furniture assembly

- Basic enclosure fastening of non-critical equipment

2. When Budget is Limited

Untransducerized tools are:

- Less expensive (50–70% less upfront investment)

- Easier to maintain

- Faster to install

You must, however, depend on manual torque verification, process checks, or calibration routines to assure performance.

Pros and Cons Summary

Transducerized Screwdrivers

Pros:

- High torque accuracy and repeatability

- Complete quality control data capture

- Enables traceability and audit readiness

- Ideal for flexible, multi-stage processes

Cons:

- Increased initial investment

- Needs controller and training

- Must be integrated with current systems

Untransducerized Screwdrivers

Pros:

- Simple to use

- Lower investment

- Established for general-purpose manufacturing

Cons:

- No torque data or traceability

- Susceptible to human error

- Limited quality assurance in regulated environments

- Real-World Example: Medical Device Manufacturer

A Singaporean medical device firm replaced conventional electric torque screwdrivers with Mountz EPT-Series Transducerized Tools in their recent production run of their robotic surgery units.

Result:

- Cut torque-related defects by 75%

- Placed all fasteners on full traceability

- Ranked zero torque-related results on ISO 13485 and FDA audits

- The upgrade ensured high-value business from major hospitals and health care groups worldwide.

Last Thoughts

As precision manufacturing changes, so also do the technologies that support them. Although plain old screwdrivers are still tolerable for everyday use, high-spec assembly businesses, product protection, and legislative requirements are speeding to embrace transducerized torque tools.

To upgrade your process of torque or just explore smart screwdriving systems, or what they offer, products like the Mountz EPT Series provide the level of control, versatility, and traceability required of production now.

Ready to Take Your Torque Control Strategy to the Next Level?

At Phil Industries, we supply Mountz transducerized and electric torque instruments for regulated and high-accuracy applications in Singapore. We provide:

- Torque tool consultation

- Demo units for testing

- Local calibration and after-sales services

Call us now to arrange a torque audit or talk to one of our assembly tool specialists.