How Cleanroom-Ready Torque Tools Help Reduce Contamination Risk in Precision Manufacturing

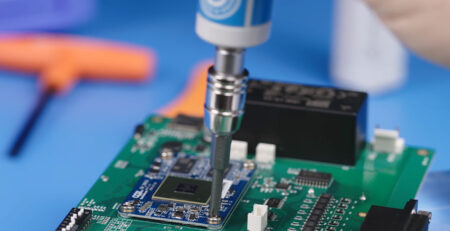

In cutting-edge manufacturing such as semiconductors, electronics, biomedical, and medical device manufacturing, contamination-free assembly is critical. Even a tiny particle or electrostatic discharge can lead to catastrophic failure in delicate parts.

That’s why the use of cleanroom-ready torque tools—especially those specifically engineered for ESD protection and particle control—is essential. Torque control ensures mechanical integrity. But if the tool itself introduces contaminants or static discharge, it defeats the purpose.

In this article, we’ll explore how cleanroom and ESD-safe torque screwdrivers—like those offered by Mountz Torque—play a critical role in reducing contamination risk, supporting clean manufacturing, and ensuring product safety and compliance.

Cleanroom Assembly Contamination Risk

In cleanroom assembly (usually Class 1000 to Class 100,000), careful particle and electrostatic discharge (ESD) control is maintained to:

- Avoid micro-contamination on wafers, board level circuit boards, and medical devicesAvoid risks of ISO 14644-1, IEC 61340, and FDA compliance

- Avoid loss of yield rates and latent defects

- Contaminants may be from:

- Clothing and skin

- Packaging components

- Poorly designed tools

✅ Torque tools—commonly employed in assembling precision parts—need to be designed to reduce particulate formation and ESD discharge. That is where cleanroom-compatible torque screwdrivers fit in.

What Are Cleanroom-Ready Torque Tools?

Cleanroom torque screwdrivers are specially manufactured using low-particulate materials, sealed cases, and non-outgassing components to ensure the high level of cleanliness in controlled environments. Some of the important features are:

- Anodized aluminum cases to reduce surface friction and particle shedding

- Stainless steel or sealed interiors to avoid lubricant migration or shedding

- Smooth finishes to facilitate easy cleaning and wipe-down operations

- Cleanroom-compatible non-shedding grips and lubricants

Example: Mountz Cleanroom Torque Screwdrivers

Mountz CLS-series Cleanroom Torque Screwdrivers are designed specifically for use in cleanrooms:

- Torque range: 1.8 – 120 lbf.in (0.2 – 13.6 Nm)

- Material controlled by particle-containing housing material

- Color-coded ring to simplify adjustment

- Cleanroom-compatible maintenance with a minimum of exposed moving parts

- Preset or adjustable models available

Reference: Mountz Cleanroom Torque Screwdrivers

⚡ Why ESD Protection Is Important Beyond Cleanroom Compliance

In cleanrooms where electrostatic-sensitive devices (ESDs) such as microchips or sensors are being loaded, static discharge is as risky as particle contamination. A 100V ESD event—humane-ly undetectable—can destroy semiconductors irreparably. That’s why ESD-safe torque tools are essential. Such tools are made of conductive or dissipative materials so that static charges can safely journey to ground.

Example: Mountz ESD-Safe Torque Screwdrivers

Mountz provides a user range of ESD Torque Screwdrivers conforming to ANSI/ESD S20.20-2021 standards:

- Torque range: 0.17 to 120 lbf.in (0.02 – 13.5 Nm)

- Made from ESD-safe composite plastics and conductive handles

- Prevent generation and discharge of static while using tools

- Preset and adjustable options available

Reference: Mountz ESD Torque Screwdrivers

✅ Benefits of Using Cleanroom-Ready Torque Tools

1. Reduces Particle Generation

- Sealed body and non-shedding coatings prevent microcontamination.

- Smooth finishes allow for easy cleaning without chemical degradation.

- Ensures ISO cleanroom compliance (ISO 14644).

2. Prevention of ESD Damage

- ESD-safe materials dissipate safely in use.

- Prevents static buildup that can discharge into circuit boards or sensitive medical instruments.

- Assists in compliance with ESD program requirements.

3. Increased Assembly Precision and Quality

- Preset models enable repeatable torque values, which minimize operator variation.

- High repeatability prevents over-torquing fragile fasteners and threaded joints.

- Ensures mechanical integrity without compromising contamination control.

4. Industry Certifications and Cleanroom Procedures Compliant

- Designed for the FDA-regulated industries, ISO 13485, AS9100, and IEC 61340.

- Integration is easy into controlled environments and ESD-protected areas (EPA).

5. Industry Applications – Cleanroom and ESD-ready torque screwdrivers are applied in:

Semiconductor & Electronics

- Chip packaging

- Wafer handling machines

- Circuit board and BGA assembly

Aerospace

- Assembly of flight-critical electronics

- Sensor and control module installations

Medical Devices & Biomedical

- Implantable device manufacturing

- Catheter and endoscope assembly

- Cleanroom drug delivery system assembly

A 0.1 Nm torque variation on a microfastener within a medical device can lead to patient risk, device failure, or compliance breach.

Mountz CLS-Series vs ESD Torque Tools: What’s Best for You?

| Feature | Mountz CLS (Cleanroom) | Mountz ESD Series |

| Cleanroom Class | ISO Class 7 & above | ESD Protected Area (EPA) |

| Particle-Safe | ✔✔✔ | ✔✔ |

| ESD-Safe | ✔ | ✔✔✔ |

| Torque Range | Moderate to High | Low to High |

| Ideal For | Medical, Pharma, Aerospace | Semiconductor, Electronics |

The most effective choice for most facilities is to have both—particularly when ESD protection and particle control are of top priority.

Best Practices for Cleanroom Torque Tool

- Evaluating Your Cleanroom Class – Select tools suitable for your facility’s cleanroom rating (e.g., ISO Class 7).

- Use Preset Models for Repeatable Production – Minimize variability by restricting torque adjustments in assembly.

- Utilize Regular Cleaning and Calibration Schedules – Clean with non-residue wipes and calibrate every 6-12 months or 5,000 cycles.

- Verify Operator Training – Even high-quality tools can be compromised without proper handling in a cleanroom.

- Choose an Authorized Distributor – Source precision torque tools with on-site calibration, replacement, and training support.

Final Thoughts

Cleanroom-ready and ESD-safe torque tools are not a luxury—they’re an absolute necessity for ensuring compliance, product safety, and production yield in sensitive manufacturing environments. By using precision torque tools from reliable brands like Mountz, Singapore and other companies can protect their products from concealed risks and infuse quality into every fastener.

Need Assistance in Selecting the Appropriate Cleanroom or ESD Torque Tool?

We provide torque solutions for high-technology applications at Phil Industries. We have:

- Mountz Cleanroom and ESD Torque Screwdrivers

- Calibration and training assistance

- Local service to semiconductor, aerospace, and biomedical customers in Singapore

Call us today to arrange a demo or consultation with a torque specialist.