Top 10 Ways to Improve Torque Accuracy in High-Tech Manufacturing

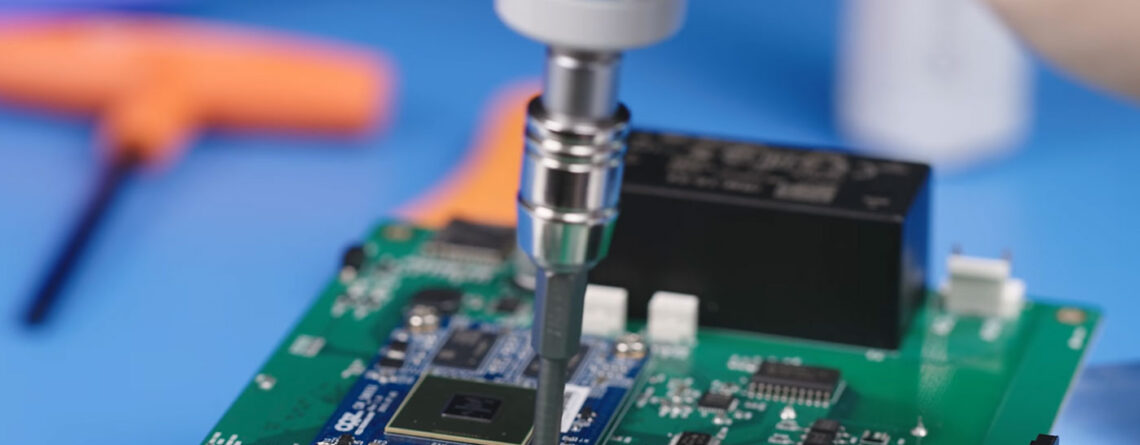

In industries like semiconductors, electronics, aerospace, biomedical, and medical devices, precision is non-negotiable. One wrong torque setting during assembly could result in product failure, non-compliance, or worse—safety hazards. That’s why torque accuracy isn’t just a preference—it’s a mission-critical requirement. In this article, we’ll explore the top 10 ways engineers, technicians, and managers can improve torque accuracy in high-tech manufacturing environments.

1. Employ the Appropriate Type of Torque Tool for the Application

The most critical element of accuracy is the selection of the correct torque tool. A torque screwdriver might be perfect for electronics, while an adjustable torque wrench would be perfect for aerospace assembly. Some of the most common torque tools are:

- Click-type torque wrenches – suitable for repetitive applications, with sound indications.

- Dial torque wrenches – perfect for calibration and verification.

- Electronic torque tools – provide real-time readings of torque and angle values.

- Pneumatic or electric screwdrivers – ideal for assembly-line use.

Tip: Always choose a tool whose torque range is as close to your desired torque setting as possible.

2. Calibrate Torque Tools Regularly

- Calibration guarantees tools deliver the stated torque value consistently. In high-spec industries, this isn’t only best practice—it’s regulatory requirement and traceability necessity.

- Recommended calibration interval: Every 5,000 cycles or every 6–12 months, whichever comes first.

- Obtain ISO 6789 certification for hand torque tools.

Pro Tip: Use on-site torque testers to check calibration prior to beginning a production run.

3. Consider Joint Conditions and Fastener Types

- Not all fasteners and materials are created equal. Joint condition (soft or hard) affects the final clamp load, even if the applied torque is the same.

- Soft joints dissipate more energy, with potential under-tightening.

- Hard joints apply more torque to the fastener.

- Learn how your fastener type (machine screw, self-tapping screw, bolt) and joint material (plastic, aluminum, stainless steel) influence torque behavior.

4. Prevent Over-Torquing and Under-Torquing

Misuse of torque can result in:

- Stripping of threads

- Component cracking

- Operational loosening

- Electrical failures (particularly in semiconductor and electronics)

- Employ torque limiters or pre-set tools to offer repeatable tightening.

- Employ a programmable threshold digital torque driver to notify the user when the proper torque is reached.

5. Invest in Lightweight, Ergonomic Tools

- Technicians in line assembly or cleanroom typically handle torque tools for hours at a time. Fatigue can directly affect torque control.

- Employ tools with ergonomic grips

- Select light, ESD-safe tools.

- Employ pistol grip electric tools for high-volume usage

- Minimizing fatigue enhances consistency, particularly in precision assembly of medical devices or electronics.

6. Keep the Workplace Clean and Controlled

- Environmental conditions affect torque consistency. Dust, humidity, and temperature changes can affect component behavior and torque measurement.

- Semiconductor & cleanroom environments must employ cleanroom-compatible tools

- Store tools in stable-temperature areas

- Employ anti-static mats and grounding to prevent ESD hazards

Tip: Clean and inspect tools regularly for oil, dust, and wear.

7. Use Torque Data Logging for Traceability

- Smart torque tools with digital feedback and data logging enable engineers to:

- Monitor tightening history

- Verify each step of the process

- Minimize manual errors

- This is particularly critical in regulated industries such as aerospace and medical devices, where each screw and bolt has to be traced.

Examples of data logging tools:

- Mountz FG Digital Torque Wrench

- Mountz EPT-Series Electric Screwdrivers

8. Train and Certify Technicians

Even the greatest tool can’t make up for inadequate technique. Technicians need to be trained in:

- Appropriate tool handling

- Pre-torque inspection

- Identifying thread or joint problems

- Mandate regular refresher training and in-plant audits to ensure uniformity.

9. Uniform Torque Specs Across Teams

- Standardization reduces variations across shifts, technicians, and production lines.

- Enforce color-coded tool sets

- Provide visual torque tables

- Include torque specs in digital work instructions

- This comes in handy when dealing with miniature screws or small parts in electronics or biomedical applications.

10. Partner with a Trustworthy Torque Tool Supplier

A trustworthy supplier does more than sell tools—they offer technical assistance, calibration services, and customized solutions. Partner with a supplier who can:

- Recommend the best tools for your industry

- Provide demo and test support

- Locally calibrate tools in Singapore

Final Thoughts

Accuracy of torque is not just making the right choice of tool. It’s assembling an entire system: qualified individuals, reproducible tools, controlled conditions, and traceable procedures. Whether it’s building a pacemaker, installing a bolt of critical importance to an aircraft, or producing a wafer handler semiconductor, accurate torque control guarantees safety, compliance, and performance.