Development of Torque Tools: From Manual to Data-Driven

Torque screwdrivers were once manual tools with visual or feel feedback. Although sufficient for low-risk applications, there is no means to guarantee and record that the proper torque was achieved. As part of the evolution of smart manufacturing and Industry 4.0, digital torque screwdrivers with real-time data logging have been a game-changer. These tools provide:

- Torque and angle measurement

- Real-time error detection

- Wireless data transmission

- Cloud or local storage of torque results

Why Recording Torque Data Matters?

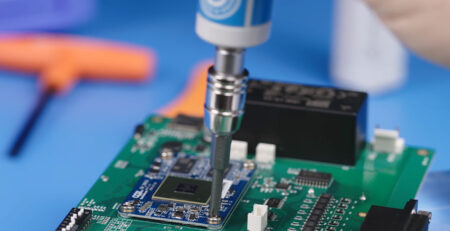

1. Ensures Assembly Consistency

Without data, you’re relying solely on human judgment—and even the most experienced technicians make mistakes. By capturing torque values at every fastening point, production teams can:

- Verify each screw is within tolerance

- Detect outliers or over-torqued/under-torqued connections

- Standardize performance across multiple shifts or technicians

This is particularly vital in semiconductor production where 0.2 Nm torque deviation will damage sensitive PCB components.

2. Facilitates Regulatory Compliance

In highly regulated markets such as aerospace and medical devices, stringent regulatory bodies like FDA, ISO 13485, AS9100, and IEC demand traceability in the assembly process. Using torque screwdrivers that record each application:

- You can provide reports for audit purposes

- You can demonstrate compliance to torque specification

- You reduce the risk of product recalls or lawsuits

A full torque trace for each serialized product unit improves your defensibility during external audits.

3. Improves Quality Control (QC) and First Pass Yield

Quality teams can review torque data to identify trends or recurring issues:

- Are torques creeping over time?

- Is one operator consistently applying more force?

- Are certain fastening points more prone to error?

With these insights, QC can intervene in advance—minimizing scrap rates, rework, and line stoppages.

In high-volume electronics assembly, a 1% reduction in rework saves thousands of dollars per month.

4. Enables Real-Time Error Detection and Process Control

Data-logging intelligent torque tools can instantly notify:

- Over-tightening

- Missed screws

- Reversed sequence

- Angle misalignment

When interfaced with Manufacturing Execution Systems (MES) or PLC systems, this enables:

- Live process feedback

- Automatic line stop on critical errors

- Operator guidance via warnings or lights

Real-time process monitoring is particularly critical in aerospace, where torque variations can undermine structural integrity.

5. Lays the Groundwork for Predictive Maintenance and Ongoing Improvement

Torque data collection is not only about managing the present process—it’s about predicting future risk. With an adequate torque data history, manufacturers can:

- Detect tool wear prior to failure

- Recognize incremental torque creep within individual tools

- Refine torque specifications according to performance trends

This aligns with lean manufacturing and Six Sigma practices—critical in competitive, high-spec environments.

6. Key Features to Look for in Torque Screwdrivers with Data Recording

When choosing a data-logging torque screwdriver, look for the following:

✔ Torque Range & Accuracy

- Select tools with ±2% or higher accuracy

- Make sure the range will fit your smallest and largest fasteners

✔ Data Connectivity

- USB, Bluetooth, or Wi-Fi data transfer

- Integration with MES, SCADA, or ERP systems

✔ Data Storage & Management

- Onboard storage (store thousands of results)

- Cloud backup or local network connection

- Export formats (CSV, PDF, API-ready)

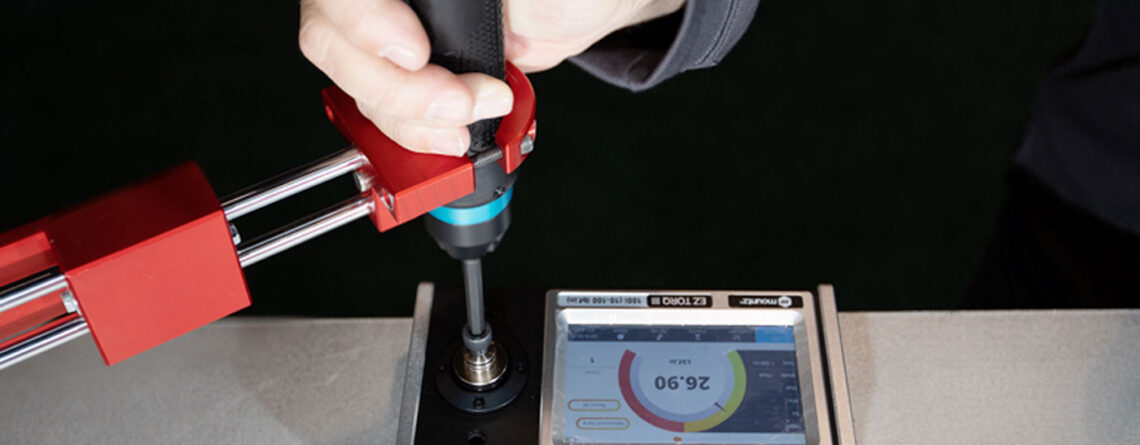

✔ User Interface

- Digital display with live torque/angle display

- Operator ID tracking

- Error code or alarm

Examples of Suitable Tools:

- Mountz FG Digital Torque Screwdrivers

- Tohnichi Digital Interchangeable Head Drivers

- Mountz EPT-Series Smart Electric Screwdrivers

7. What’s in a Torque Data Record?

This aligns with lean manufacturing and Six Sigma practices—critical in competitive, high-spec environments. Each torque data point can contain the following, depending on the tool and system being used:

- Date and time

- Operator ID

- Torque value applied (e.g., 0.75 Nm)

- Angle of rotation (where applicable)

- Pass/fail outcome

- Workstation ID or work order number

- Part serial number

This degree of granularity not only provides assurance of traceability but opens the potential for analytics, optimization, and accountability.

Use Case: Electronics Assembly Line

A Singapore-based EMS (electronics manufacturing services) provider recently incorporated Mountz smart screwdrivers with data logging into their mobile phone assembly line.

Result:

- Decreased torque-related defects by 43%

- Increased audit pass rates

- Reduced manual inspection time by 30%

- Achieved full compliance with Tier 1 client requirements

This investment paid for itself in less than 6 months due to reduced rework and increased client confidence.

Final Thoughts

In today’s precision-driven manufacturing landscape, torque control without documentation is like flying blind. Engineers and managers must move beyond manual practices and embrace tools that provide data-driven validation for every torque application.

From an airplane’s control units to a sensor on a surgical device, torque data logging provides a degree of reliability, quality, and operational excellence that cannot be met by manual systems.

Need Help Selecting a Torque Screwdriver with Data Logging?

At Phil Industries, we supply intelligent torque tools from the world’s top brands such as Mountz, designed for industries that accept no compromise. We also offer calibration, operator training, and system integration.

Call us today to arrange a free demo or to discuss with a torque consultant how to upgrade your production line.