5 Tips to Sustain Your Torque Tools’ Accuracy Long-Term

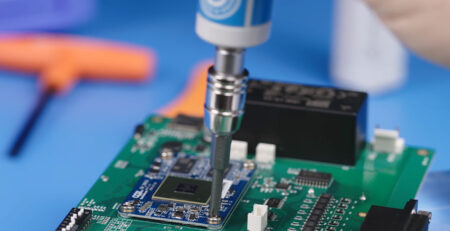

When it comes to torque tools, accuracy is paramount. Being off by a few percentage points can result in a fastener that’s too loose—or too tight—leading to catastrophic failure, compromised safety, or rejected QA lots. For sectors like semiconductors, electronics, aerospace, and medical devices, torque inaccuracy is more than a quality problem—it’s a compliance risk.

Regular maintenance is the key to ensuring long-term precision, reducing downtime, and extending the lifespan of your tools. In this article, we’ll walk through 5 essential torque tool maintenance tips that every engineer, technician, and maintenance manager should know.

1. Calibrate Your Tools on a Scheduled Basis

Calibration is the most important maintenance task—and the one most often overlooked. Why Calibration Matters:

- Prevents over-torque and under-torque errors

- Complies with ISO 6789, ASME, and FDA requirements

- Ensures traceability for quality control and audits

Recommended Calibration Frequency:

- Every 5,000 cycles or every 6–12 months, whichever occurs first

- After any tool is dropped, damaged, or subjected to extreme temperatures

Pro Tip: Employ an in-house torque tester to confirm torque prior to each usage, particularly for high-criticality assemblies such as medical implants or aerospace.

2. Store Tools in a Clean, Controlled Environment

Environmental conditions are essential to torque consistency and tool life. Best Practices for Storage:

- Avoid humidity: May cause mechanical components and springs to corrode

- Shield from dust and ESD: Utilize anti-static cases in clean rooms and electronics laboratories

- Avoid vertical hanging of torque wrenches (particularly click-type): May cause constant tension on the internal spring

Checklist for Storage:

- Utilize padded, specialty toolboxes or foam inserts

- Prominently label calibration dates

- Store tools at room temperature (shun extremes)

Tip: Clean tools after every use—especially when used in oil, chemical, or solder environments.

3. Train Operators to Properly Use Tools

Misuse is a primary cause of premature torque tool failure. Training Must Cover:

- Correct torque application technique: Apply slow and steady pressure

- Do not “jerk” the tool

- Observe torque limits: Don’t apply tools in excess of their rated capacity

What NOT to Do:

- Do not use torque wrenches as breaker bars

- Don’t pry or drop tools

- Don’t “test” tools by overtightening

Tip: Provide refresher training every 6 months, particularly in high-turnover settings such as cleanroom assembly.

4. Make Visual and Functional Checks a Habit

Operators should conduct a quick pre-use inspection before each shift or job. Visual Checks:

- Is the tool bent, cracked, or rusted?

- Are grip areas worn or slippery?

- Are markings or digital readouts clear?

Functional Checks:

- Does the click mechanism function?

- Is the ratchet engagement smooth?

- For digital devices, is the display showing correctly and responding immediately?

- Is the torque value returning to zero properly?

✅ Record all deviations or inconsistencies for a technician to examine immediately.

5. Collaborate with a Reputable Torque Tool Service Partner

Occasionally do-it-yourself maintenance is not sufficient—particularly for high-precision digital devices or torque drivers applied in high-risk fields such as aerospace or biomedical engineering. What a Good Service Partner Provides:

- Factory-certified calibration

- Tool repair and replacement parts

- Maintenance records and calibration certificates

- Recommendations for the newest torque tool technologies

Leading suppliers will carry top brands such as:

- Mountz Torque

- Tohnichi

- Sturtevant Richmont

- Gedore

- Norbar

✅ Dealing with a Singapore-based supplier of torque tools with local support and calibration will save time, cost, and compliance risk.

6. Bonus: Care Tips for Digital Torque Tools

With the increasing smart manufacturing, many engineers are using these days’ digital torque tools to provide real-time torque monitoring and traceability. A few more care tips:

- Use OEM-approved batteries and chargers only

- Store in cushioned, anti-static cases

- Firmware updates as needed

- Zero-reset prior to each use to prevent digital drift

✅ Mountz FG Digital Torque Wrench or EPT-Series Screwdrivers are a few of the instruments that have built-in torque and angle measurement—perfect for Industry 4.0 settings.

Final Thoughts

Torque tools are similar to surgical instruments—they must be accurate, dependable, and properly maintained. In markets where every micro-component or bolt must adhere to strict safety and compliance regulations, tool maintenance isn’t a choice—it’s a requirement.

With regular calibration, storage, user training, pre-use inspection, and aligning with trusted partners, you can maximize tool life, prevent expensive failures, and provide torque consistency throughout your line.