ESD Black Frosted PP Plastic Sheet Anti Static PP Partition

| Place of Origin: | China |

| Brand Name: | allesd |

| Certification: | ISO/SGS |

| Model Number: | AC053 |

| Minimum Order Quantity: | Negotiable |

| Price: | Negotiable |

| Packaging Details: | 1pc/box |

| Delivery Time: | 7-10 working days |

| Payment Terms: | T/T |

| Supply Ability: | 100,000pcs per month |

- Description

Description

Detailed Product Description

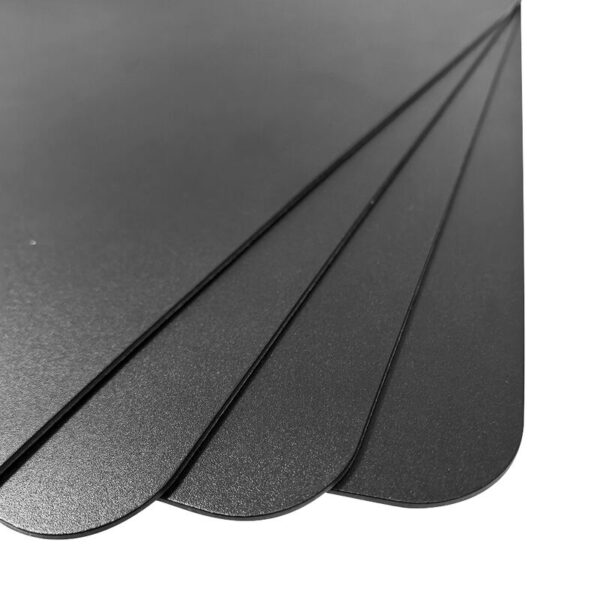

ESD Black Frosted PP Plastic Sheet Anti Static PP Partition

This is a permanent anti-static polypropylene sheet with a black frosted surface, measuring 555mm x 320mm, designed specifically for electrostatic protection and isolation purposes. It dissipates static electricity through its own material properties and is used to create isolation barriers in sensitive electronic work environments to prevent damage caused by electrostatic discharge (ESD).

Description:

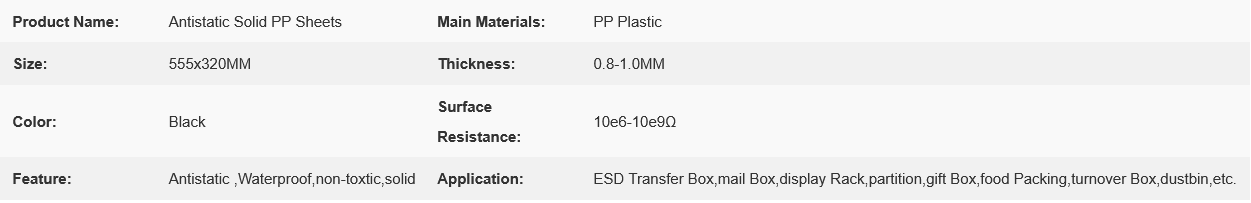

| Product name | Antistatic Solid PP Sheets |

| Main Materials | PP Plastic |

| Size | 555x320MM or Customized Sizes |

| Thickness | 0.8-1.0MM |

| Color | Black Customized |

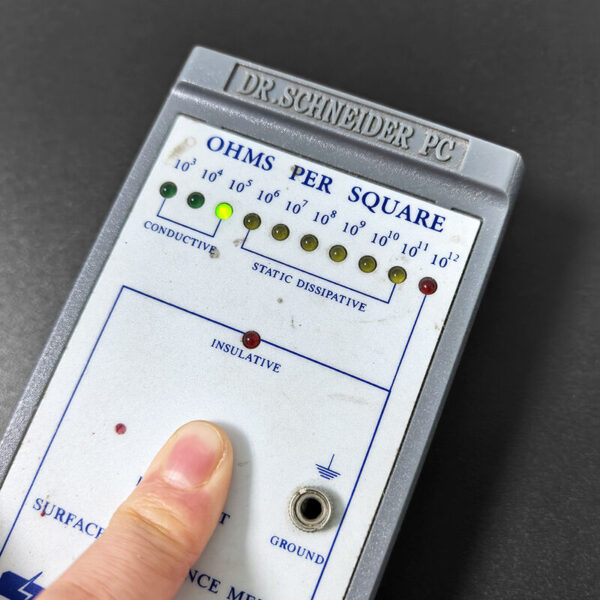

| Surface Resistance | 10e6-10e9Ω |

| Applications | ESD Transfer Box,mail box,display rack,partition,gift box,food packing,turnover box,dustbin,etc. |

1. Core materials and functions

Substrate: Polypropylene (PP plastic), which has the characteristics of light weight, chemical corrosion resistance, and good mechanical properties.

Core function: It has permanent anti-static (ESD) performance, which can effectively prevent static electricity accumulation and is used to protect electronic components or products that are sensitive to static electricity.

2. Physical specifications

Size: 555mm x 320mm sheet. This is a specific cutting size that may be customized for the isolation needs of certain equipment or work areas.

Color and Appearance: Black, Frosted surface. A frosted surface helps reduce reflections, hide scratches, and may provide better tactile and writing performance (if marking is required).

3. Interpretation of Key Characteristics

Anti Static PP Partition “: It clearly states that its ultimate use is as a partition board/partition. This means that it is likely to be used for:

Electronic assembly and maintenance workbench.

Separation within shelves, turnover boxes, and pallets.

Local area isolation on the production line.

Any situation where static sensitive items need to be physically isolated from the general environment and anti-static measures are required.

4. Typical application scenarios

SMT workshop, chip packaging, hard disk assembly, precision instrument maintenance and other electronic manufacturing and maintenance fields.

Used as a pad or isolation barrier on an anti-static workbench, or placed in an anti-static container as a partition insert.

Create a local, physical barrier for areas that require electrostatic protection.